Composite Decking Resources

Do’s and Don’t for Deck Installation

Advising your best interests.

Please read the instructions fully before starting to install. Failure to install composite decking correctly will result in the deck becoming structurally unstable. A 10mm gap around the whole deck must be left for expansion and a 5mm gap between board ends.

1. DO this when installing.

![]() Leave a 10mm Gap around the deck perimeter to allow for movement.

Leave a 10mm Gap around the deck perimeter to allow for movement.

![]() Ensure there is good air circulation around and under the whole deck.

Ensure there is good air circulation around and under the whole deck.

![]() Leave a 5mm Expansion Gap between board ends.

Leave a 5mm Expansion Gap between board ends.

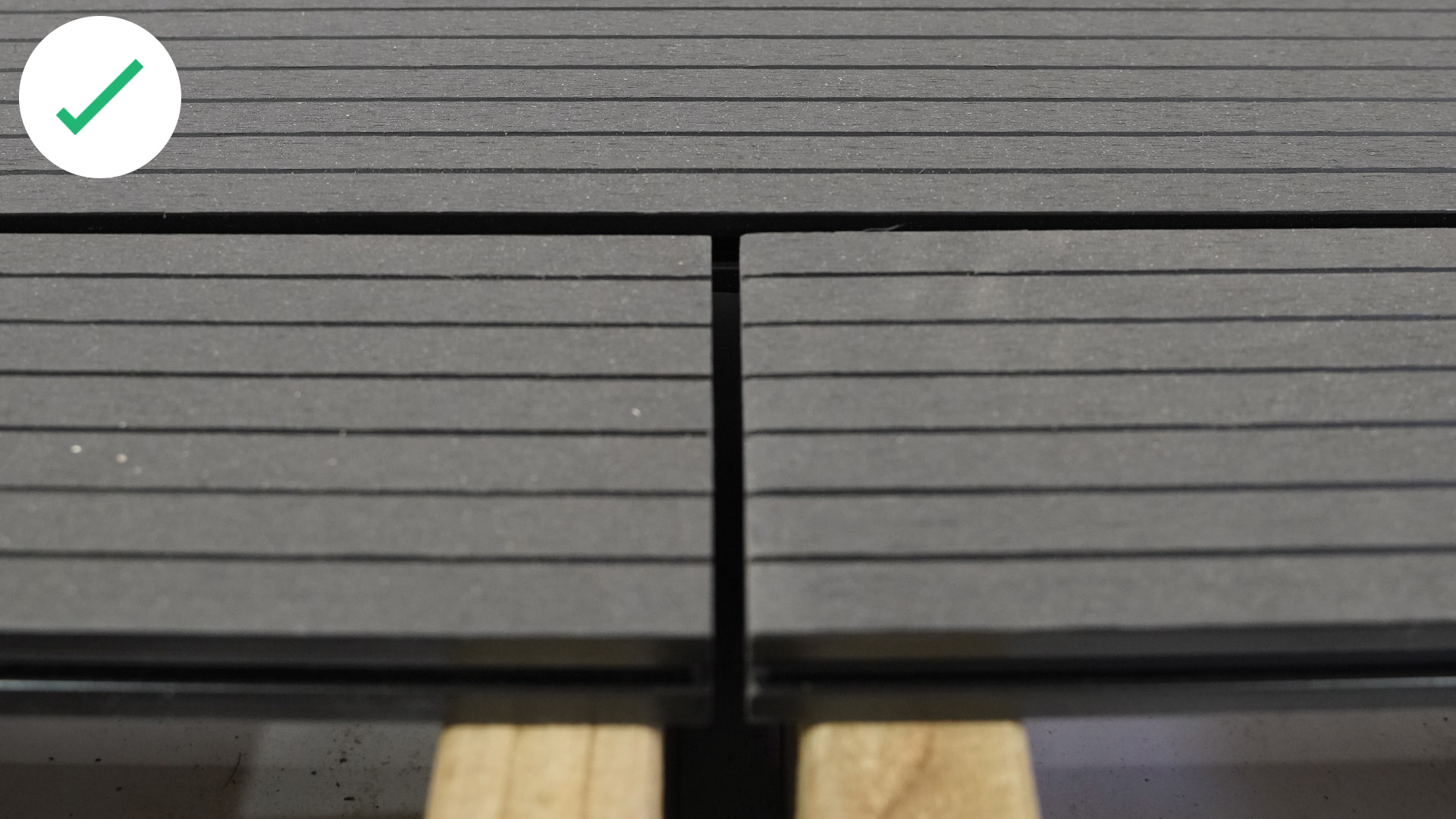

![]() Double joist where board ends meet. Each board end should have its own clip and joist.

Double joist where board ends meet. Each board end should have its own clip and joist.

![]() Use Steel installation kits for fixing to steel aluminium joists.

Use Steel installation kits for fixing to steel aluminium joists.

![]() Use good quality joists or aluminium. Pre drill fascia boards before fixing.

Use good quality joists or aluminium. Pre drill fascia boards before fixing.

![]() Use recommended clips to secure boards to joists.

Use recommended clips to secure boards to joists.

![]() Pre Drill Steel joists to receive stainless steel screws.

Pre Drill Steel joists to receive stainless steel screws.

![]() Acclimatise boards to the environment for 3 days prior to installation.

Acclimatise boards to the environment for 3 days prior to installation.

![]() Leave a natural fall to allow water to drain off boards.

Leave a natural fall to allow water to drain off boards.

![]() Use locking clips to control even expansion & contraction along the length of the board.

Use locking clips to control even expansion & contraction along the length of the board.

![]() 20mm Maximum overhang from joist at deck edges with last fixing clip max 30mm from board end.

20mm Maximum overhang from joist at deck edges with last fixing clip max 30mm from board end.

*Steel / Aluminium joists >2mm: A hole must be pre drilled in the joist and specific Steel Joist Installation Kits must be used.

2. DO NOT do this when installing. ![]()

![]() Screw directly through boards and composite joists.

Screw directly through boards and composite joists.

![]() Store boards on solid or uneven surfaces.

Store boards on solid or uneven surfaces.

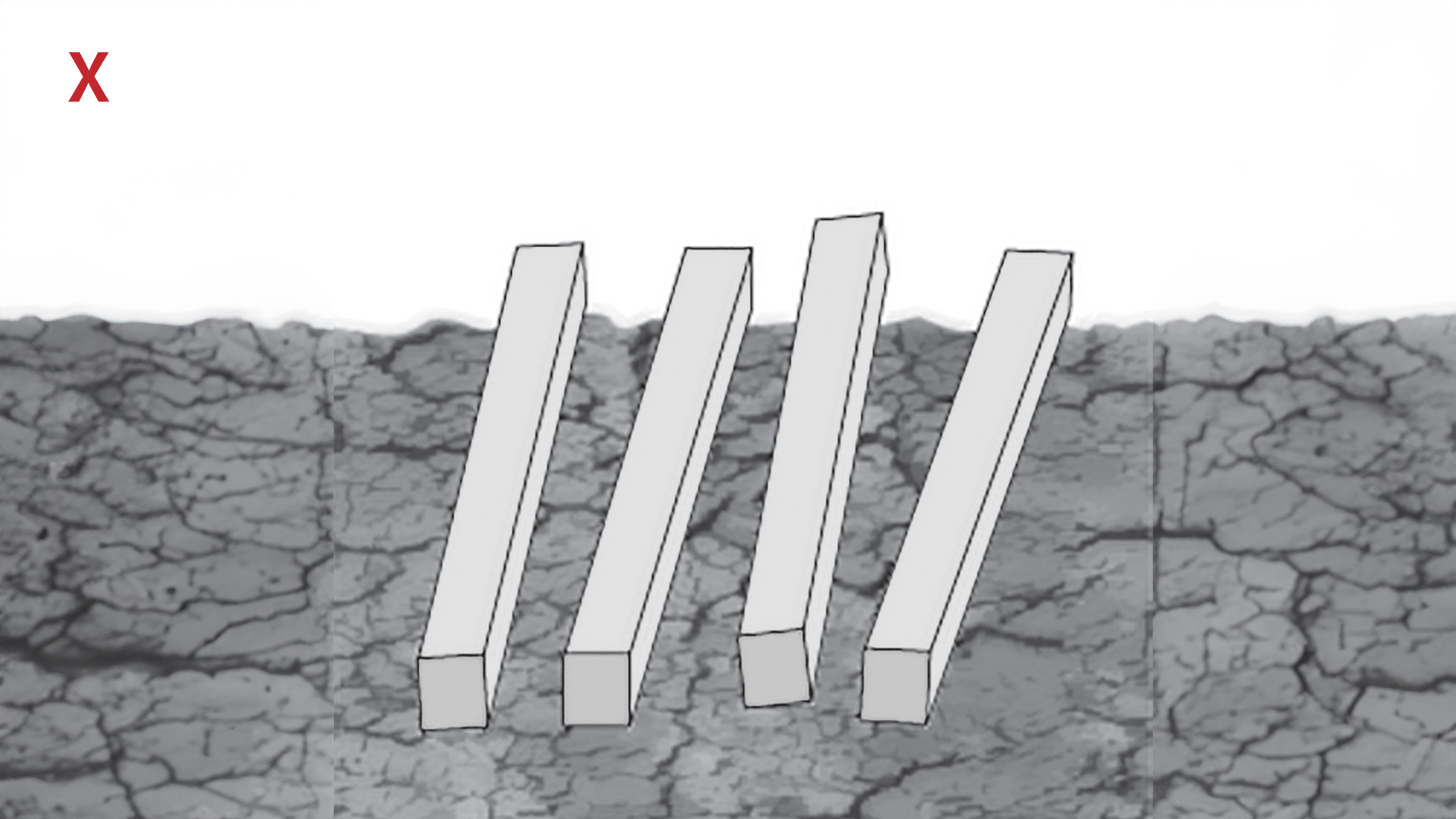

![]() Install in areas that have wall on all sides

Install in areas that have wall on all sides

![]() Leave butt jointed and cut ends unsealed.

Leave butt jointed and cut ends unsealed.

3. Bridging Supports

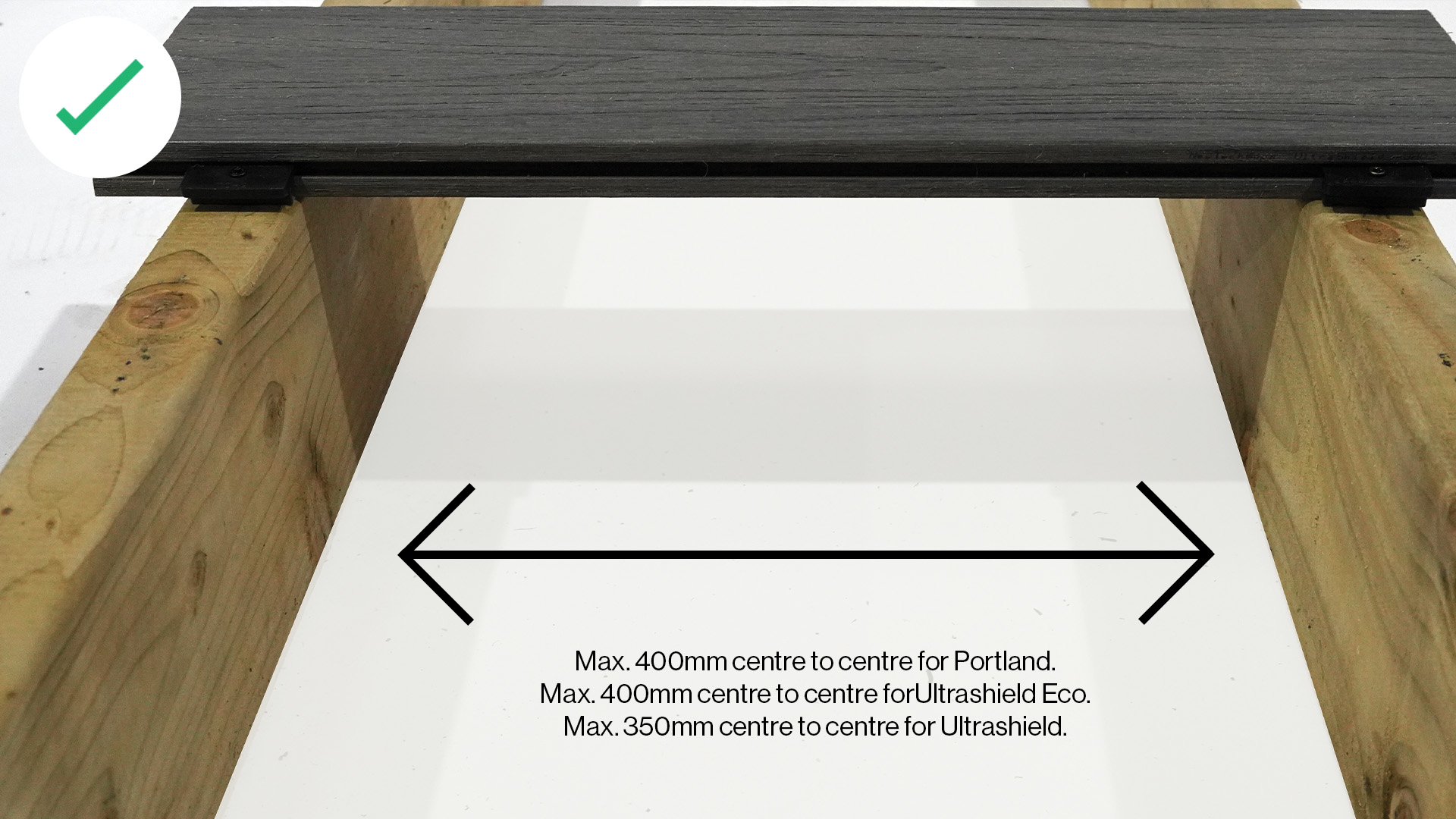

4. Structural Sound Subframe

5. Clips and Fixings

Note: Due to the production process for Ultrashield decking board widths can vary slightly. Boards widths should be measured and matched accordingly.

6. Joists

7. Board Overhang

8. 5mm Gap For Expansion