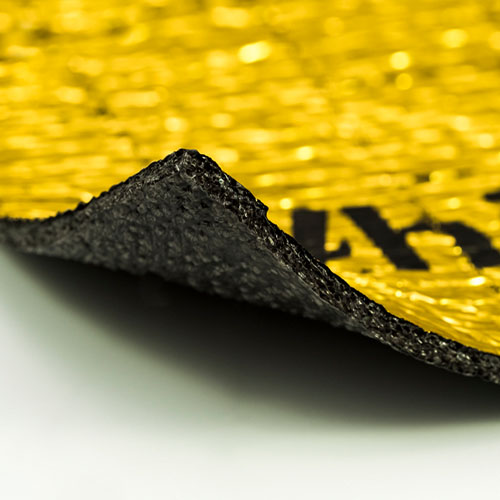

4.5MM SOUND MASTER PRO CORK RUBBER

10m2

UNDERLAY

Whiteriver Code: F1010024

Categories: All_products, Flooring Accessories, Laminate Flooring, Underlays

Description

| QUANTITY PER ROLL | 10m2 |

|---|---|

| ROLL SIZE | 4.5mm x 1m x 10m |

| TOG RATING | 0.75 |

| SOUND IMPROVEMENT | 18dB |

| UNDERFLOOR HEATING Y/N | Yes |

| COMPRESSIVE STRENGTH | Excellent |

| HEAT TRANSFER RESISTANCE | 0.075 k/w m² |

| THERMAL INSULATION | Excellent |

| DENSITY | 700kg / m² |

| PRODUCT CODE | F1010024 |

• REDUCES IMPACT NOISE TRANSFERRING TO LOWER FLOORS IN APARTMENTS AND HOMES

Laying Instructions

- Area of installation must be dry, dirt and dust free and weather tight. If over 75% RH, 2.5% C.M, 4% C.M use VERMEISTER SF DPM PRIMER on concrete subfloors. To determine RH, please use a Hygrometer. Timber subfloors should have a moisture content of 10-12%. For any installations outside of the above conditions please contact Whiteriver.

- Whiteriver Soundmaster Pro should be left for a minimum 8 hours or ideally overnight at the place where it is to be installed, to allow for any potential shrinkage.

- The subfloor must be sound, smooth and dry. A self-levelling compound may be required to achieve the desired ‘SR’ level requirement.

- When bonding to bare concrete, a suitable concrete sealer is recommended to ensure maximum adhesive coverage and bond strength.

- When installing timber flooring over Whiteriver Soundmaster Pro always use a flanking strip around the perimeter to reduce impact transmissions into walls.

- When installing ceramic tiles, stone and vinyl flooring leave at least a 3mm gap around the perimeter which should be filled with a flexible sealant.

Storage: Whiteriver Soundmaster Pro must be stored indoors. At no time must the Whiteriver Soundmaster Pro be exposed to the elements of the weather. Whiteriver Soundmaster Pro must always be kept dry, otherwise moisture will build up in the material and will subsequently make bonding to the subfloor more difficult. Moisture may also cause the material to curl and ripple at the edges once unrolled. It is recommended that the polythene packaging be removed in the area where it shall be applied.